The main conveniences of a magnetic belt conveyor depends on its own ability to relocate iron components that would certainly or else be difficult to handle. These components include a large variety of metals including steel, iron, and also aluminum, which are frequently made use of in manufacturing and development procedures. Magnetic belts give a safe hold on these components, avoiding all of them from slipping, falling, or ending up being removed. For instance, in reprocessing plants, steel fragment needs to have to be separated coming from various other products for effective handling. Magnetic belt conveyors create this activity less complicated through enticing and securing onto the steel, guaranteeing it remains in area as it the bearer system. This gets rid of the requirement for hands-on sorting, decreasing the time as well as effort needed to distinct components, as well as improving the overall effectiveness of the procedure.

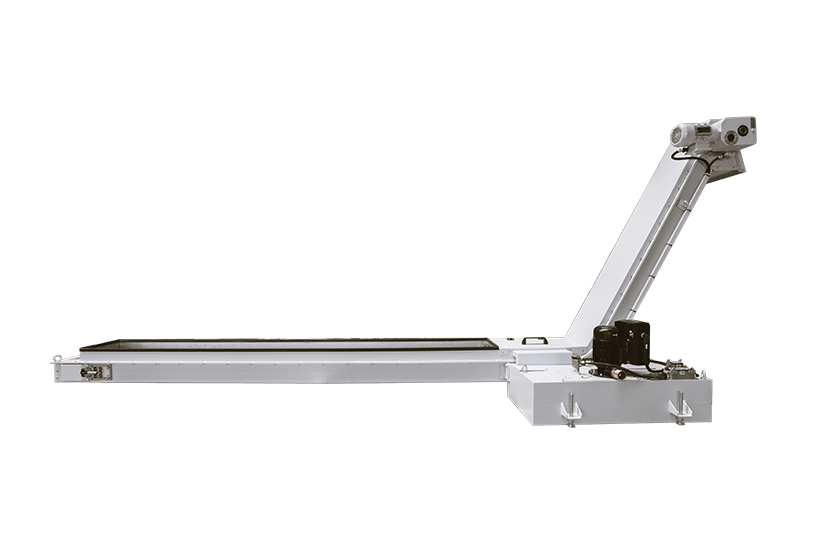

Another considerable perk of Magnetic Belt Conveyor is their flexibility. These bearers may be made to work in various positionings as well as setups, depending on the particular demands of the procedure. Whether products require to become relocated flat, vertically, or even at an slope, magnetic bearers could be individualized to satisfy the creation line's style. Additionally, various styles of magnets may be used to make magnetic field strengths along with differing strengths, producing it achievable to transfer components of numerous dimensions as well as weights. The use of electromagnets, for instance, enables for the durability of the electromagnetic field to become adjusted as needed to have, delivering flexibility when taking care of different iron products. This adaptability creates Magnetic Belt Conveyor ideal for a variety of treatments, coming from small production to large reprocessing procedures.

Productivity is an additional key perk offered through Magnetic Belt Conveyor. Conventional bearers depend on abrasion between the belt and also the products being carried, which can easily lead to damage on the body, bring about higher servicing costs as well as recurring substitutes. Magnetic Belt Conveyor, meanwhile, make use of the electromagnetic field to keep the materials in position without rubbing, lessening endure the belts and other parts. This function supports a lot less routine maintenance and less breakdowns, allowing the unit to work consistently along with low down time. Industries that require fast assembly-line production, such as the vehicle or food handling markets, gain from the continuous, smooth procedure of magnetic conveyors. Their potential to maintain a stable circulation of components guarantees that businesses can easily keep higher performance as well as stay clear of costly hold-ups. To acquire further details please go to www.tecnimetal.com/de/project/magnetbandfoerderer/

Another substantial benefit of Magnetic Belt Conveyor is their reduced maintenance needs. Unlike conventional bearers that count on friction to move components, magnetic belt bearers utilize the magnetic power to handle steel products, minimizing the wear and tear on the belt itself. This indicates that the belt experiences less rubbing and also, consequently, much less damage as time go on. Consequently, companies take advantage of fewer replacements of deteriorated parts, which lowers routine maintenance costs. Magnetic Belt Conveyor are actually likewise effortless to well-maintained, along with their components created for simple disassembly and servicing. In fields like meals processing, where cleanliness is actually a priority, Magnetic Belt Conveyor could be set up to be actually cleaned up rapidly and also efficiently, making sure compliance with health specifications.

Magnetic Belt Conveyor also result in workplace security through automating the transport of dangerous materials. In business such as exploration, where stinging metallic components or unsafe scrap components prevail, magnetic bearers can take care of harmful materials without the demand for hand-operated interference. This lessens the threat of worker traumas that may or else happen when taking care of massive or sharp items. The design of Magnetic Belt Conveyor, along with their tough structure and protected component dealing with, helps avoid collisions that might occur if components were actually left ignored or even by hand raised. Also, because magnetic bearers give even more control over the movement of products, they additionally lessen the possibility of incidents such as product spills or machinery jams, guaranteeing a safer working setting for workers.